Bookkeeping

Work in Process WIP Inventory

Content

The cost of purchasing a product factors into what it costs to make it (e.g., raw materials, labor, and production). Thus, your ending WIP inventory is essential to know for inventory accounting. Inventory is a current asset account found on the balance sheet, consisting of all raw materials, work-in-progress, and finished goods that a company has accumulated. These might be sheets of metal for manufacturing vehicles, timber for property construction, or bales of fabric for clothing. Or they may be products in their own right, such as nuts and bolts for the vehicles, or buttons and thread to make the clothing.

This is because inflated WIP ties up capital and may inflate the tax burden. It’s also simply good practice to keep WIP inventory as slim and optimized as possible for overall inventory management. The WIP account is updated on a regular basis, typically at the end of each accounting period or within preset intervals like monthly, quarterly, or biannually. Or, it can be automatically kept up to date by using manufacturing software like an MRP system.

Work In Process accounting

The similarity of the words may lead some businesses to mistake “process” for “progress” when researching these inventory costs. This ending WIP inventory is listed as a current asset on your company’s current balance sheet. So, to figure out how to find work in process inventory you need the beginning work in process inventory. And to calculate that, you need the ending work in process inventory. Finished Goods – These are the completed goods you have assembled and are ready for sale.

The cost of WIP inventory is a bit more complex than determining the value of finished goods, as there are many more moving parts. Before attempting to calculate your current WIP inventory value, here are some terms you will need to know first. Work-in-process is an asset, and so is aggregated into the inventory line item on the balance sheet . This content is for information purposes only and should not be considered legal, accounting, or tax advice, or a substitute for obtaining such advice specific to your business. No assurance is given that the information is comprehensive in its coverage or that it is suitable in dealing with a customer’s particular situation. Intuit Inc. does not have any responsibility for updating or revising any information presented herein.

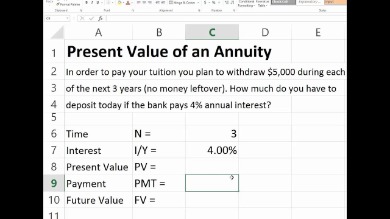

Work in process inventory formula

The reason for this is that WIP is in the process of being turned into finished goods. Once the goods are completed and packaged, they’re considered finished goods. However, if it’s taking longer than a year to turn WIP into finished goods, it might be classified as a long-term asset.

What are the 4 components of inventory?

While there are many types of inventory, the four major ones are raw materials and components, work in progress, finished goods and maintenance, repair and operating supplies.

You need to find a supplier that meets your needs and doesn’t take too much time, money or resources. In contrast, Work-In-Progress refers to a production process that requires a longer time frame. Besides these costs, ABC also incurs manufacturing overheads in the form of worker benefits, insurance costs, and equipment depreciation costs. ABC already has $100,000 worth of raw material inventory left over from the previous year and makes additional purchases of $300,000 to manufacture new television sets for this year.

Work in Process Inventory (WIP): Definition, Formula, and Examples

Because of the varying time horizons and the possibility of differing costs, using a different system will result in a different value. Analysts must account for this difference when analyzing companies that use different inventory systems. There is an interplay between the inventory account and work in process inventory includes the cost of goods sold in theincome statement — this is discussed in more detail below. Variable production overheads are allocated to units produced based on actual use of production facilities. Fixed production overheads are often allocated based on normal capacities or expected production.

Therefore, the total value of all unfinished products is considered Work-in-Process inventory for accounting purposes. Although you can’t sell these goods, include them as an asset on your balance sheet. WIP inventory should also be an asset when determining your company’s value to attract investors or obtain funding. Accounting-wise, figuring out WIP inventory helps determine your inventory’s actual value for tax considerations. Work-In-Process refers to the materials that have started the production process, but have not yet been completed.

The Work-in-Process Inventory Account – A Practical Exercise:

As such, the difference between WIP and finished goods is based on an inventory’s stage of completion relative to its total inventory. Is a complete solution for inventory management, offering everything from one-click processing and mobile scanning to inventory analysis and reporting. It has everything you need to keep your products, customers, and transactions synced and secure, freeing you up to focus on your business.

What is included in work in process inventory quizlet?

manufacturing costs, i.e direct materials, direct labor and manufacturing overhead are combined in the production to become work in process inventory. after production process is completed ,work in process becomes finished goods.